After doing three EcoTracks research trials at SUNY-ESF’s Heiberg Forest in Tully, NY, we did a fourth trial, this time in the Catskills. Not only did we change location, but we beefed up from a Timberjack 360 cable skidder to a John Deere 648H grapple skidder.

In late September 2020, we completed the fourth and final trial for the Eco-Wheel Tracks research project. Each trial was designed to measure the effect of three different skidder wheel cover types (bare tires, chains, and tracks) and increasing traffic (0 to 12 skidder passes) on soil compaction and rutting. In an earlier blog, I summarized the first two of three trials that were completed at SUNY ESF’s Heiberg Forest. The fourth trial took place in Delhi, NY, working with loggers Keith Clark and Nick Weir and their 2008 John Deere 648H grapple skidder.

The leaves were just starting to change color and the weather was sunny and warm. We were lucky to have such a stunning backdrop to complete this study.

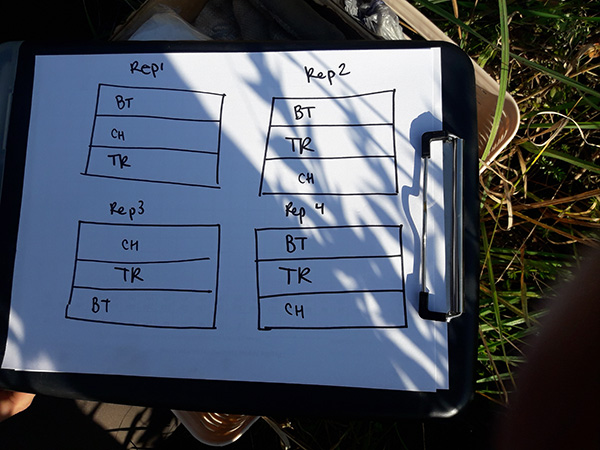

As at Heiberg, we set up the study plots to include four replications of the three skidder wheel cover types. We had 12 travel lanes measuring 6 meters wide x 20 meters long, with four lanes each dedicated to bare tires, chains, and tracks.

In addition to driving the skidder through the study plots, Keith and Nick also assisted with field data collection. Here’s Nick measuring the ground profile to estimate rut depth as a result of traffic. Profile measurements were made in each lane at 0, 4, 8, and 12 skidder passes.

Taylor Richmond using the slide hammer to collect a soil sample for bulk density analysis. Soil samples were collected within, and in between, the skidder wheel paths at 0, 4, 8, and 12 passes.

Each soil core consisted of two samples, one from 0-5 cm deep and the other from 5-10 cm deep.

As with any field research endeavor, we ran into a few challenges, most of which were related to Delaware County’s notoriously rocky soils.

The rocky soils put the slide hammer through its paces and we sheared off the core sampler cap again! Thanks to Heather, Jim and Nick for welding it back together.

We were hard-pressed to make a measurement of soil mechanical resistance down to 10 cm without first hitting a rock or two. We measured mechanical resistance within, and in between, the skidder wheel paths before traffic and after each of the 12 skidder passes.

However, our team was full of problem-solvers and we got the 144 skidder passes, 192 bulk density samples, 936 measurements of mechanical resistance, and 48 soil profiles necessary to complete the trial. I think we even had fun doing it.

Get back to work!

For me, it was an eye-opening experience just to see how these tracks are installed.

Keith and Nick tightening down the tracks.

By the time you read this blog, Taylor will have presented the preliminary results of this study at the online Society of American Foresters meeting (Oct. 29-31, 2020) and may well be on her way to completing her Master’s thesis. Her research makes an important contribution to reduced-impact forest operations research in the NYC Watershed. No other study has evaluated the environmental performance of Eco-Wheel Tracks used on skidders.

Next week, I will document how we remediated the ruts associated with skidder traffic at this site. Thanks to everyone that helped to complete this work.

Done and dusted! Front row: Taylor Richmond. Back row (left to right): Karl VonBerg, Kris Brown, Keith Clark, Heather Hilson, Nick Weir, and Andrew Krutz.

For more blogs on the eco-wheel research, check out the following:

Do Eco-Wheel Tracks Reduce Soil Compaction Associated with Skidder Traffic?

Smoothing Out Ruts at the Eco-Wheel Tracks Study Site